Success story

Expo OSAKA 2025 (Japan)

The Spanish Pavilion at Expo 2025 in Osaka: An interactive cultural experience.

The Osaka Expo 2025, Japan, is a World Expo that took place from April 13 to October 13, 2025. This international event was held under the theme ‘Designing Future Society for Our Lives’, aiming to address and find solutions to contemporary global challenges through innovation and collaboration.

Spain, like other countries, had its own pavilion, where it showcased its culture, innovations, and contributions to the main theme of the expo. The audiovisual engineering and systems integration of the Spanish pavilion were carried out by the company BGL, which included the coordination and design of the audiovisual equipment that provided an interactive and immersive experience for visitors, thus highlighting the cultural narrative that Spain presented at the world exhibition.

Necessary connections to move trusses

“We wanted to control the motors of trusses where we had installed projectors. This way, we could lower the entire truss during maintenance and raise it again without the need to use auxiliary means to carry out the necessary tasks”

As Silvia Miranda from the BGL engineering department explains, they needed AV boxes to connect the movement motors of some trusses to facilitate equipment maintenance and thus avoid using auxiliary means such as scaffolding or elevating platforms, optimizing time and ensuring personnel safety.

By having an automated system that controls the lowering and raising of the trusses, it becomes easier to access the projectors for cleaning, adjustment, or lamp replacement, as well as for any other necessary technical review. This translates into a smoother operation, minimizing service interruptions and allowing greater flexibility during installations.

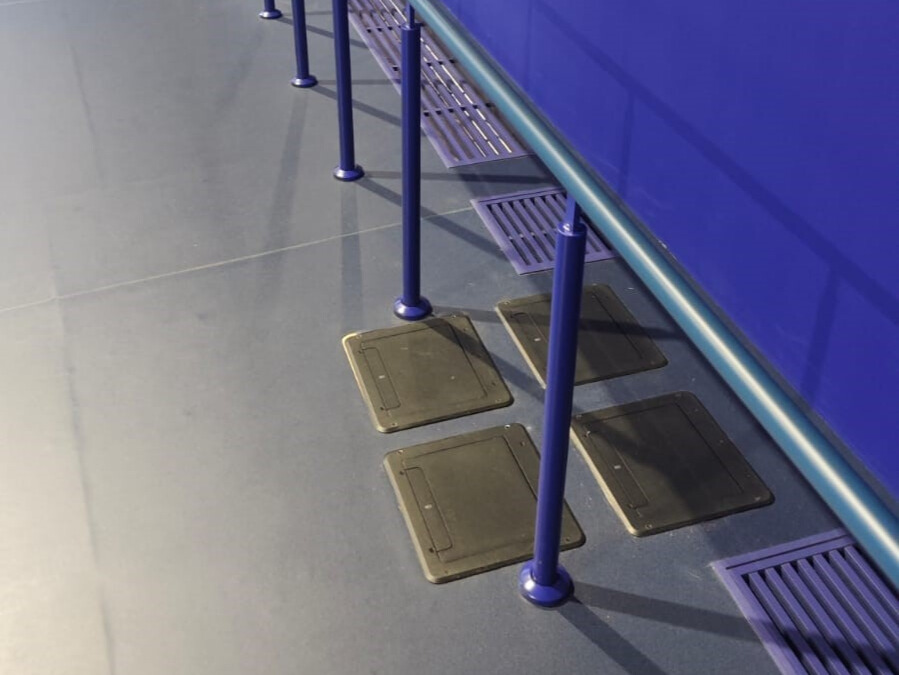

With these requirements, 6 custom-made floor boxes were manufactured for BGL, featuring a TB AT lid with panels that included: Female CEE 32A 5 pole connectors and Male CEE 16A 4 pole connectors, to supply the necessary power for the motors in a practical and safe manner, with the connections flush-mounted in the floor.”

Photo: Spanish Pavilion at the Osaka 2025 Expo. Courtesy of Silvia Miranda

Photo: Custom-made TB AT floor box for BGL.

“They were easy to install and performed their function perfectly”

“The custom-designed and manufactured TB AT boxes featured a panel with male CEE 16 A connectors and female CEE 32 connectors for controlling truss motors, allowing maneuvers to be performed quickly, comfortably, and safely.”

TB AT secure and robust box for floor installation

TB AT boxes are custom-made with the following features:

- Extruded aluminum box with lid.

- Lid can be closed with cables connected. Perpendicular connection to the floor.

- Box to be recessed in the floor.

- Complies with EN60670-1 and EN60670-23 standards according to the Low Voltage Directive 2014/35/EU.

- Maximum load capacity (compression test at 20 ± 3°C, 10 mm/min): 12,670 N.

- Custom-designed and manufactured product.

Custom-made solutions. Without limits.

As in all our projects, the products used in this installation have been custom-developed, adapting to the client’s specific needs. At Pínanson, we don’t offer standard solutions, but rather exact solutions: size, connection type, color, and even free screen printing with your visual identity. If you have a technical need that doesn’t yet exist on the market, we can design, manufacture, and ship it to you anywhere in the world. We offer the same quality, customer service, and commitment that characterizes us.