An ordinary day at Pinanson. The telephone rings:

– Nidia, I have 10 floor boxes installed in a room and we can’t touch the surface, the hole is what it is!. The problem is that the closures are plastic and I have 7 of them without the lid (they broke the first week of use) Do you have any quick solution?

Does this situation sound familiar to you?

If so, you are among the 50% of integrators that installed boxes with plastic parts that do not have a practical and easy opening and remain open most of the time with the risk (quite probable) of break up when stepped on.

– Don’t worry, there is a solution. From what you tell me, I see two alternatives:

- Replace the boxes with a similar ones (since the hole “is what it is”) and be more careful when closing the lid.

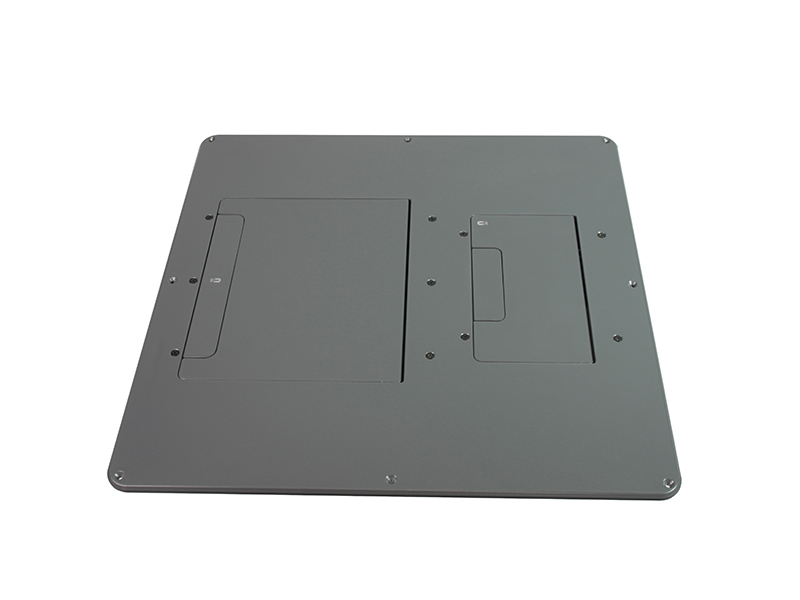

- Replace them with custom-made boxes (since the hole “is what it is”) made of a more resistant, durable metal material… When closed, the lid will not be an obstacle when stepped on. Recognizing that day to day is complicated and it is difficult to monitor that all the lids of the boxes are closed correctly every time they are used.

– My advice is to choose option 2

Following our advice, the client prefers this solution. The next step is to know the dimensions of the hole, the connectors needed and the color of the box.

A few days later, we receive another call:

– Nidia, we have already received the boxes. Everything perfect

In 6 days, our client has the custom-made solution in their installation: 7 PINANSON TB AT floor boxes made of extruded aluminum, black color and with the connectors inserted in the panel (also extruded aluminum) for the specific hole they had.

In addition, the boxes include one of those details that make us different. Whenever the client wants it, in addition to the texts that are needed, we print the company logo (our client’s client) on each box, showing it visible to the user every time they open them.