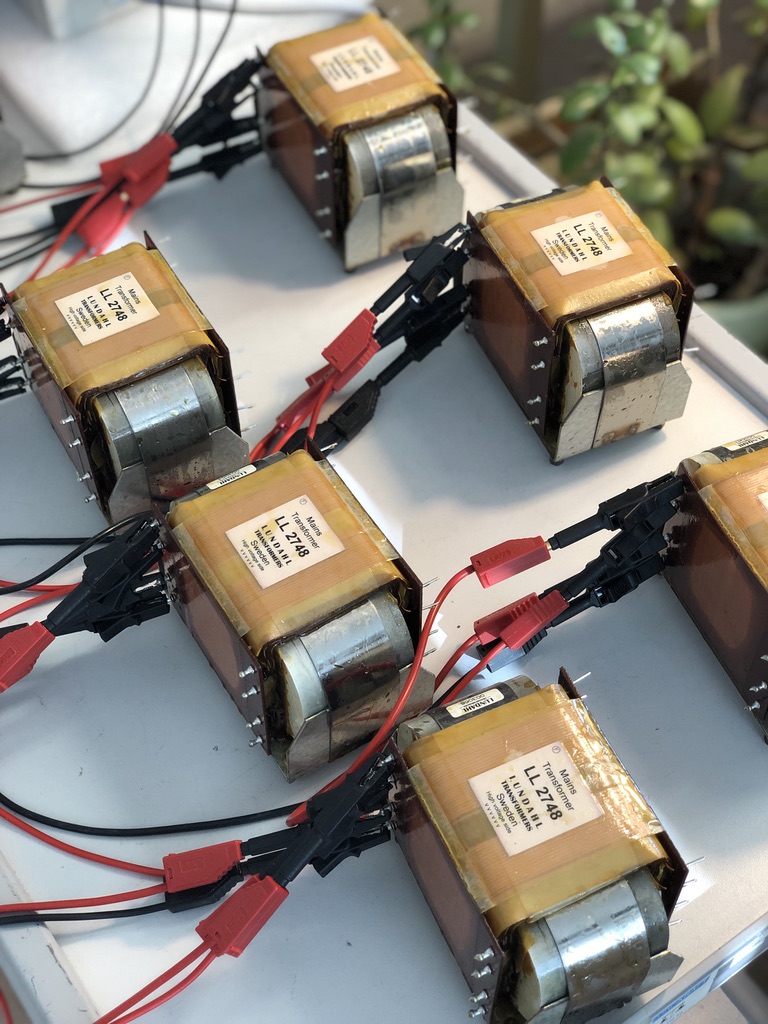

Our audio distribution equipment such as press splitters, micro-line splitters for audio production, isolators… are manufactured with high-quality transformers for professional use.

At Pinanson we have been manufacturing our splitters and stage boxes with transformers from the Swedish brand Lundahl for more than 20 years. And who better to answer some transformer questions than Per Lundahl, owner and CEO of Lundahl Transformers since 1995.

Photos: courtesy of Lundahl Transformers

1. In relation to the transformer manufacturing process, what would you say is the most critical point?

We think the winding process is the most critical point, both for performance and for consistency. For this reason all our winding machines has been designed and built in-house, with ability to insert insulation foil between each individual layer of copper wire, instead of just between sections.

2. When we talk about Lundahl transformers, we talk of high-quality transformers, why?

We put a lot of effort into making audio transformers for the best possible sound reproduction, from design to final tests. In addition to building our own manufacturing equipment we control the entire manufacturing process including housings, pin plates, annealing of housings and cores etcetera.

3. Why is there so much difference in price between audio transformers that have the same function?

Price depends primarily on the effort and care you place in a product, and of course to some extent to the cost of material. Making one of our audio transformers involves up to 50 production steps, where each step must be carefully performed and monitored. A Volkswagen and a Ferrari has similar “functions”, but very different price tags.

4. What is a Faraday shield used for?

The Faraday shield is an electrical ground plane between transformer sections. The purpose is to improve common mode rejection by reducing the capacitive coupling between windings.

5. Why does Lundahl not mention input and output impedance of transformers in his technical data?

We think the concept of transformer input and output impedance in most cases are misleading.

The impedances you usually refer to when you mention input and output impedances of transformers are not properties of the transformer, but of the application.

For a “600 ohm – 600 ohm” transformer, the DC resistance of the primary winding can be 25 – 100 ohms, and the no load impedance (measured with an open secondary) is often around 5 kohms at 50Hz, and is frequency dependent.

Input impedance will be 600 ohms only if secondary is loaded with 600 ohms, and output impedance should be in the magnitude of 100 ohms in order to properly drive a 600 ohms load.

6. What is the fundamental difference between input and output transformer?

An input transformer is a high impedance device, which should only to a very small degree load a signal line. You should be able to add or remove several listeners to an audio line (almost) without a change of signal level.

An output transformer should be an enough low impedance device to be able to drive the above line, without a change of signal level when several (high impedance) listeners are connected or disconnected from the line.

In conclusion:

input transformer = high impedance transformer, output transformer = low impedance transformer

7. When and why is the cable that connects to the transformer important?

An audio system is not better than its’ parts. If you use fine transformers, make sure that you also use fine cables.

However, we try to avoid more “audiophile” discussions on cables.

8. How can a transformer be deteriorated and stop working properly?

A well-made, well impregnated transformer almost never stops working unless it is damaged physically, most often (as they are most vulnerable) by bending pins or unsoldering the transformer for a new application.

“Pínanson, the power of the invisible”